Numerical Study of the Hysteresis Phenomenon related to Unstart/Restart in Scramjet Engines

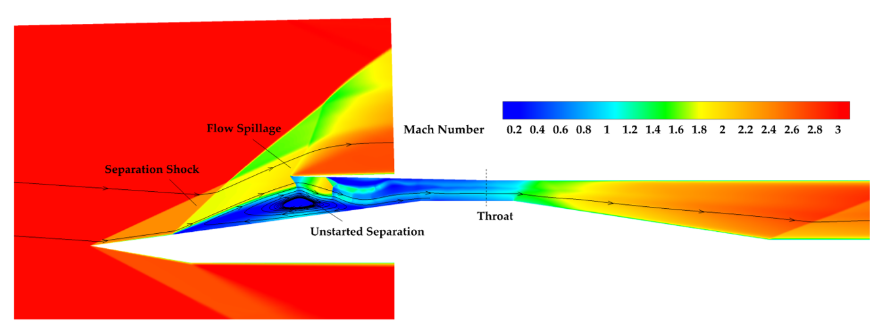

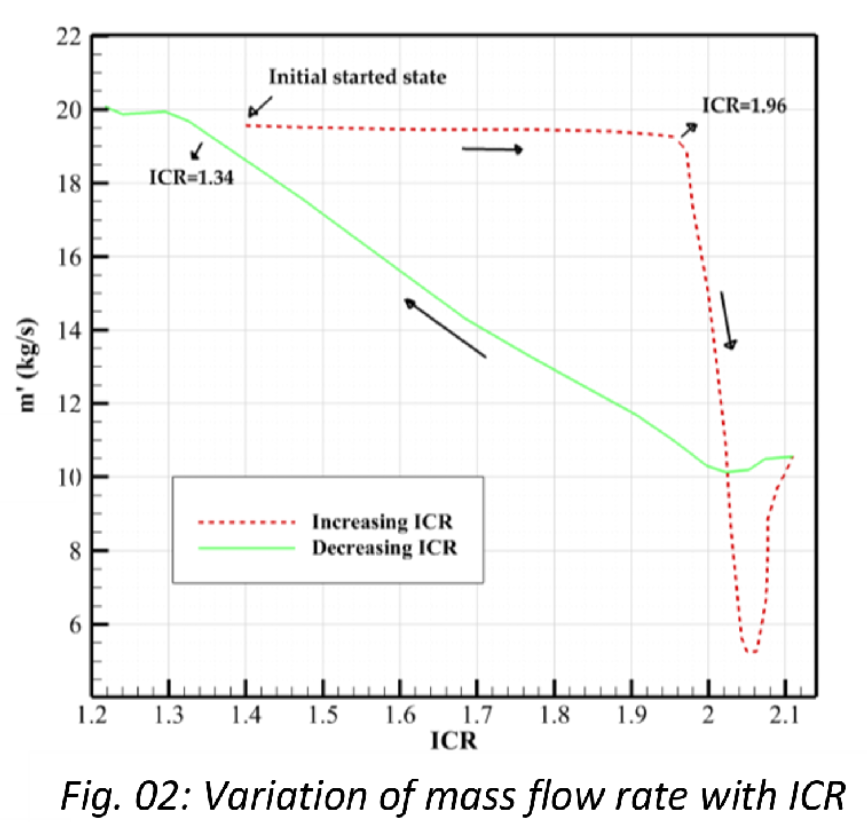

The study involves the creation of a variable geometry supersonic inlet that alters the internal contraction ratio (ICR) to simulate the unstart process. This process involves the inlet transitioning through start, unstart, and restart states, known as flow hysteresis. Two-dimensional unsteady numerical simulations were conducted using a dynamic mesh technique, focusing on a freestream Mach number of 3.0. This Mach number is relatively low and is typical for the second stage of a Turbine Based Combined Cycle (TBCC). The simulation was run for 590ms, with unstart occurring at 260ms followed by the restart phase.

The study involves the creation of a variable geometry supersonic inlet that alters the internal contraction ratio (ICR) to simulate the unstart process. This process involves the inlet transitioning through start, unstart, and restart states, known as flow hysteresis. Two-dimensional unsteady numerical simulations were conducted using a dynamic mesh technique, focusing on a freestream Mach number of 3.0. This Mach number is relatively low and is typical for the second stage of a Turbine Based Combined Cycle (TBCC). The simulation was run for 590ms, with unstart occurring at 260ms followed by the restart phase.